Memory in the Brains and Brawn of a Modern, Smart Factory

In a modern, automated factory, real-time adaptive operations are enabled by seamless communication between the AI-powered industrial controllers and the autonomous machines on the shop floor—the brains and brawn of a smart factory.

These smart factories depend on automation systems that rely on memory.

The systems and industrial controllers that are the big brains of the smart factory need scalable, fast memory.

- The brains of the factory are increasingly AI-powered industrial controllers with vast amounts of computing power and high-performance memory. Industrial Controller memory may involve storing data off-site, typically in cloud servers or centralized databases in storage appliances at the edge.

- Data stored in the cloud can expand to virtually unlimited capacity and enable collaboration between robots with access to the data. The challenges are similar to those of data centers—expanding capacity within a finite space and power envelope, minimizing latency, and maximizing uptime: network bandwidth, uptime, and security present other challenges.

- If a factory's AI brains are CPU-based, memory may be high-performance modules and SSDs. However, as memory capacity limits and costs become hurdles, new GPU-based AI industrial controllers may turn to advanced solutions like CXL® memory.

The industrial robot is the brawn in the factory. Its memory is muscle memory.

- Onboard embedded memory allows robots to store and retrieve critical data needed for real-time decision-making. Whether it’s sensor readings, control algorithms, or task-specific parameters, memory enables efficient computation.

- With local memory, robots can continue their tasks even if they lose connectivity to external industrial control systems. Local memory ensures that essential information remains accessible.

- On-board memory stores safety protocols, emergency stop signals, and other critical instructions. In emergency situations, quick access to this information is vital.

- Placing the “muscle memory” directly within the robot enables low latency and autonomous operation, but the operational environment, finite space, and need for data persistence create challenges.

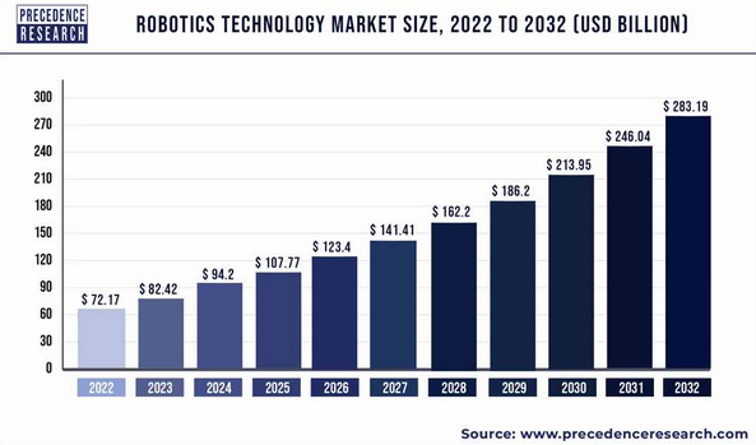

Robotics Technology Forecast

While robotics technology forecasts vary on the absolute number, they share one thing in common – a Compound Annual Growth Rate of nearly 16%.

Recent forecasts see the market size tripling in the less than a decade.

As robotics and industrial controllers go up, its important to secure a steady stream of memory for both the control and robotic ends of the system.

SMARTsemi is your supply chain partner for DRAM components, eMMC solutions, and SD/microSD Flash Memory Cards for long-life applications. With 20+ years of industry experience, we understand your challenges and have aligned our priorities with yours to simplify your memory chip supply chain for the long run. We know what you need before you need it. Get a jump start and request a sample today.