Why Industrial Grade Matters

Industrial applications are increasingly operating autonomously with minimal human intervention. In that environment, the demands regarding quality and reliability for memory components are stringent. From the outside, commercial and industrial grade products often look similar or even identical. A commercial grade DRAM can have the exact same density, speed, and form factors as its industrial grade twin. However, an industrial-grade component is far from interchangeable with its commercial-grade counterpart (but you could use an industrial-grade device in a commercial application when supply shortages dictate). You may save costs at purchase, but you are likely to pay for it manifold later. Misusing a commercial standard memory chip in an application that requires an industrial grade component can result in a higher failure rate, data loss, and even system shutdowns.

Similar but different

With stringent requirements regarding reliability, quality, and endurance, industrial standard memory components are specifically developed for mission-critical and adverse environmental applications. There is no room for error in many sophisticated industrial applications, including medical and defense equipment. In these safety and life-critical technologies, unplanned shutdowns need to be avoided at all costs. One can easily understand that a (small) malfunction because of an unreliable memory chip can have terrible consequences. Congruently, memory components for industrial applications often need to perform in harsh environments for extended periods of time. On location, it is not rare for applications in telecommunication or defense to be subject to extreme temperatures, moisture, altitudes, dust, vibrations, and shocks. In many industrial applications, updates, repairs, or replacements in the field are cumbersome. All components need to be reliable, durable, and secure over the long haul. As a consequence, industry grade chips are subject to rigorous testing procedures and come with warranty protection, guaranteeing the required reliability for the corresponding applications. Industry certifications ensure their performance, stability, reliability, and durability.

Made to last

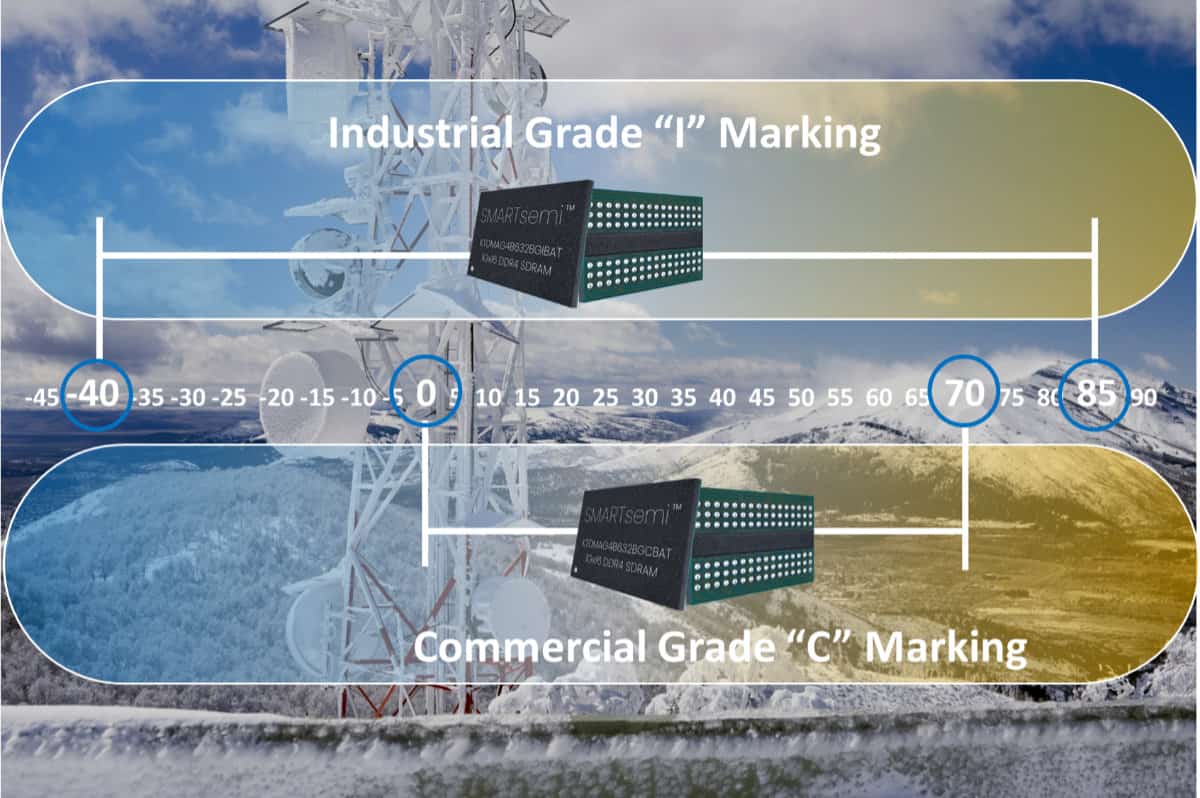

Below the surface, there are many profound differences between chip components developed for consumer products versus industrial applications. One typical component characteristic that distinguishes industry from commercial grade products is the temperature range in which it can be used safely. For consumer grade applications, the temperature rating is 0°C to +70°C, while industrial grade components can operate for extended periods at a wider temperature range of -40°C to +85°C.

Manufacturers of industrial components must adhere to a controlled build of materials (BOM). Every change or customization needs to be accompanied by a product change notification (PCN). Commercial grade components are not subject to the same levels of control. Changes to the products are often made within their – usually shorter - lifetime without notice. Typically, not only the lifetime but also the life cycle of commercial grade chips is shorter, matching the shorter life cycle of standard consumer products. With a longer lifetime and generally a more long-term availability, industry grade ICs are the sensible choice for long-life applications.

Like clockwork

Selecting the right component for an application is determined by a long list of specifications, including whether or not it meets industry standards. In environments where equipment needs to run like clockwork for decades, stringent deployment requirements with regard to quality, reliability, longevity, safety, and durability are crucial. Industrial grade components are designed, produced, tested, and certified with that in mind, usually even specific to certain industries or applications.

SMARTsemi is your supply chain partner for DRAM components, eMMC solutions, and SD/microSD Flash Memory Cards for long-life applications. With 20+ years of industry experience, we understand your challenges and have aligned our priorities with yours to simplify your memory chip supply chain for the long run. We know what you need before you need it. Get a jump start and request a sample today.