Dealing with Memory Chip Component End of Life (EOL)

While new fabs are being announced across the globe, there is a concomitant effect playing out in the background: product obsolescence. Suppliers are recovering from the slowdown during the pandemic in part by focusing on new production lines driving an increasing number of components to End-of-Life (EOL). At the other end of the supply chain, component EOL has a significant impact on every aspect of the manufacturer’s business, especially on companies developing and producing long-life applications.

The two-speed challenge

The disparity in life cycle length between products and the embedded memory components they are designed with makes dealing with memory chip EOL a constant issue. In industries developing enduring products, it is not uncommon to have up to 70% of electronics become obsolete before system fielding and single components going through EOL up to ten times during the system’s life cycle. With supply chains under increasing stress due to external and internal factors, as well as accelerating technology cycles, this two-speed challenge eats up a lot of resources and impacts not just engineering and procurement but also R&D, finance, marketing, sales, and customer support.

Memory chip component EOL is inevitable; the question is not if it will happen but when. The stakes are too high in today’s competitive world to stay in catch-up mode. The considerable cost of component obsolescence in a product’s life cycle warrants early efforts to de-risk its supply chain. Memory chip component EOL forces companies to invest resources to prevent reliability concerns, (re)design incompatibilities, and in some cases even regulatory and security issues.

Proactive design

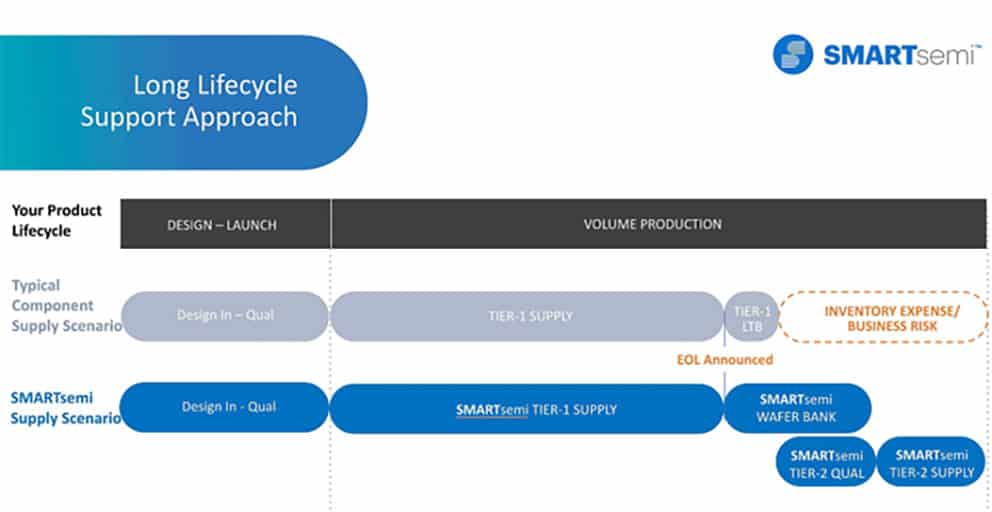

Last Time Buy (LTB) opportunities offered by chip makers buy manufacturers time to find alternative memory components or redesign the system. From a financial standpoint, the warehousing of parts can become costly as it not only ties up capital but also poses the risk of purchasing too much or too little EOL inventory. A cost-effective plan for component obsolescence today can avoid more expensive consequences later as component shortages snowball into issues in product development, operations, customer support, finance, marketing, and sales.

Without a proactive plan, redesign is often the only option but traditionally also the most expensive strategy to deal with component EOL. Less drastic than a full redesign is to find a similar component close in fit, form, and function to the memory chip in EOL and modify it for the application. Companies that apply a systematic approach to obsolescence management can optimize the value of devices and systems throughout their life cycle. By choosing the right components in the design phase and proactively mitigating EOL issues before they arise, organizations can reduce costs in a matter of months.

Addressing EOL Challenges

Comprehensive obsolescence management entails developing an integrated view of all EOL components, alternative suppliers, possible similar components, and the costs connected to the corresponding mitigations. This strategy enables companies to attain more transparency in their supply chain, understand future EOL challenges, and how to address them efficiently.

The most effective strategy to circumvent nonrecurring engineering costs spent on dealing with memory chip EOL is to identify an alternative supplier for the component or to multisource. The screening and verification of the alternative components for quality, capabilities, and authenticity start with identifying and ordering a sample for qualification. Choosing a trusted supplier like SMARTsemi with life-long product support saves procurement and engineering time, resources, and money now and in the future.

SMARTsemi is your supply chain partner for DRAM components, eMMC solutions, and SD/microSD Flash Memory Cards for long-life applications. With 20+ years of industry experience, we understand your challenges and have aligned our priorities with yours to simplify your memory chip supply chain for the long run. We know what you need before you need it. Get a jump start and request a sample today.