Evaluating the Lifecycle Costs of FLASH Memory Components

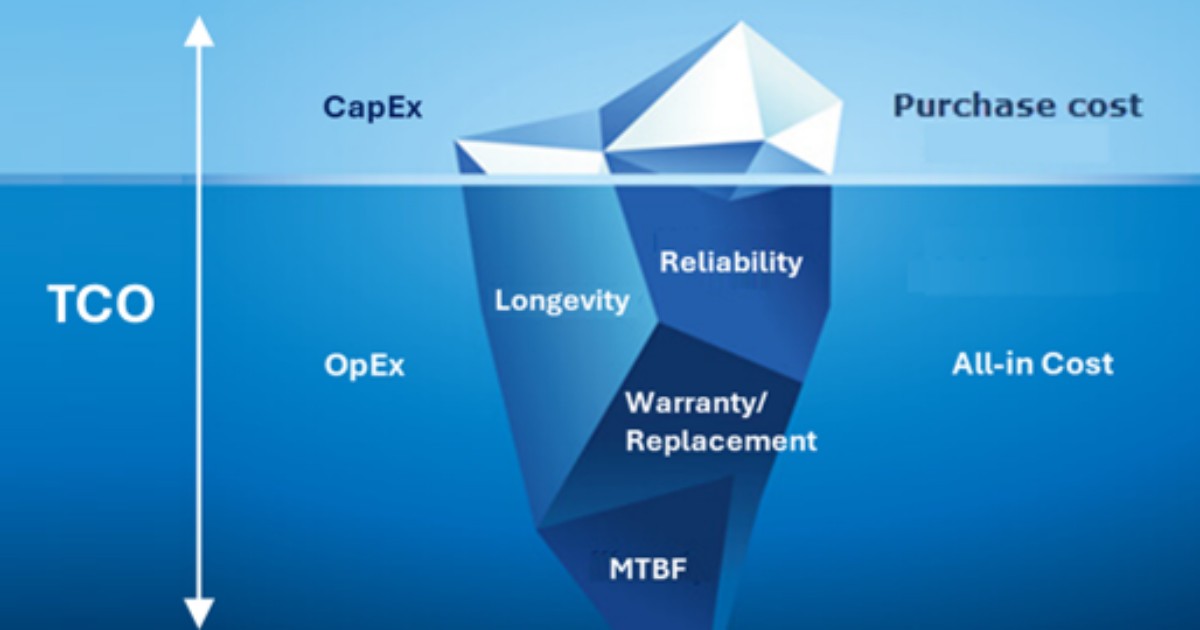

When procuring FLASH memory components like SD cards, microSD cards, and eMMCs, understanding the lifecycle costs is crucial for making informed purchasing decisions. The upfront cost is usually the primary focus – it is easy to understand and straightforward to incorporate into the budget. However, according to industry studies, that covers only 20% of the total cost of ownership (TCO). A comprehensive evaluation must consider the TCO, which includes aspects such as longevity, reliability, failure rates, and replacement costs. Here is a detailed look at the factors one should consider when selecting cost-effective FLASH memory solutions.

Beyond the price tag

The initial purchase price of SD cards, microSD cards, and eMMCs is the most visible cost component. Prices vary based on capacity, speed, brand, and other technical specifications. Higher-endurance and higher-capacity products typically come with a premium price tag. While it may be tempting to opt for cheaper alternatives, it is essential to consider whether these products meet the necessary performance and durability requirements.

The longevity of a FLASH memory component significantly impacts its lifecycle cost. Endurance is often measured in terms of the number of write/erase cycles the memory can handle before failure. For instance, industrial-grade SD and microSD cards are designed to endure more cycles than consumer-grade variants, which translates to longer lifespans in demanding applications. eMMC components, often used in embedded systems, also offer varying endurance levels. Understanding the endurance rating and matching it with the application's demands can help avoid premature failures and additional replacement costs.

Hot and cold

Industrial environments can also expose electronic components to extreme temperatures. Therefore, it is crucial to select memory components that can operate within a wide temperature range. Typically, industrial-grade SD cards, microSD cards, and eMMC are designed to function reliably from -40°C to +85°C. Ensuring that your memory components can withstand such temperature extremes will prevent failures and maintain performance in harsh conditions.

Reliability and durability

The reliability of FLASH memory components is another critical factor. High failure rates can lead to increased costs due to data loss, system downtime, and the need for frequent replacements. When procuring embedded memory components, working with a trusted manufacturer or distributor that offers quality and reliability is key. Reviewing product datasheets and seeking customer feedback can provide insights into the typical failure rates and reliability of different memory products.

Data retention refers to the duration that data remains intact on the memory component without power. In industrial and embedded applications, long data retention is crucial. Additionally, physical durability against environmental factors like temperature extremes, humidity, and vibrations can affect the lifecycle cost. Components that are robustly designed to withstand harsh conditions can save costs associated with environmental damage.

The cost of failure

The costs incurred when a component fails are usually so high that processes and systems are put in place to prevent this from happening by replacing the components before it is too late. The frequency of replacements directly impacts the total cost. This is especially important in long-life applications, like medical equipment, automotive applications, industrial robots, networking/communications tools, and defense equipment. High-quality FLASH memory components may have a higher upfront cost but lower replacement frequency, resulting in cost savings over time. Maintenance costs, including the labor required to replace and configure new memory components, should also be factored in. For SD or microSD cards, replacement seems simple at first sight. However, with equipment often operating out in the field, swapping memory cards can turn out to be cumbersome and costly. Using durable, high-endurance products can reduce the frequency and complexity of maintenance, leading to lower long-term expenses.

The right fit

Ensuring compatibility with existing systems and achieving the required performance levels are also vital. Incompatible or underperforming memory components can cause system inefficiencies and additional costs related to troubleshooting and system modifications. Choosing components that meet or exceed performance specifications ensures smooth operation and can prevent costly system downtime. Finally, the warranty period and the level of support provided by the manufacturer can influence the lifecycle costs. Extended warranties and robust support services can provide peace of mind and reduce the financial impact of unexpected failures.

Evaluating the lifecycle costs of SD cards, microSD cards, and eMMC involves more than just comparing initial purchase prices. By considering factors such as longevity, reliability, data retention, replacement costs, and manufacturer support, procurement specialists can make informed decisions that optimize the total cost of ownership. Investing in high-quality, durable memory components can lead to significant cost savings and enhanced system performance over the long term.

SMARTsemi is your supply chain partner for DRAM components, eMMC solutions, and SD/microSD Flash Memory Cards for long-life applications. With 20+ years of industry experience, we understand your challenges and have aligned our priorities with yours to simplify your memory chip supply chain for the long run. We know what you need before you need it. Get a jump start and request a sample today.