Managing end-of-life to extend production lifecycle

It has been 75 years since scientists made the first working transistor at Bell Labs after first conducting more than two decades of research. Ten years later, Gordon Moore predicted the annual doubling of transistors on a chip, dubbed Moore’s Law – an economic driver and self-fulfilling prophecy pushing the industry towards continuous innovation. Whether it is a legacy technology or the latest generation, chip components are unceasingly combined to create more complex systems and products. Each of those components has its own lifecycle, forcing engineering and procurement to think ahead.

Prevention instead of remediation

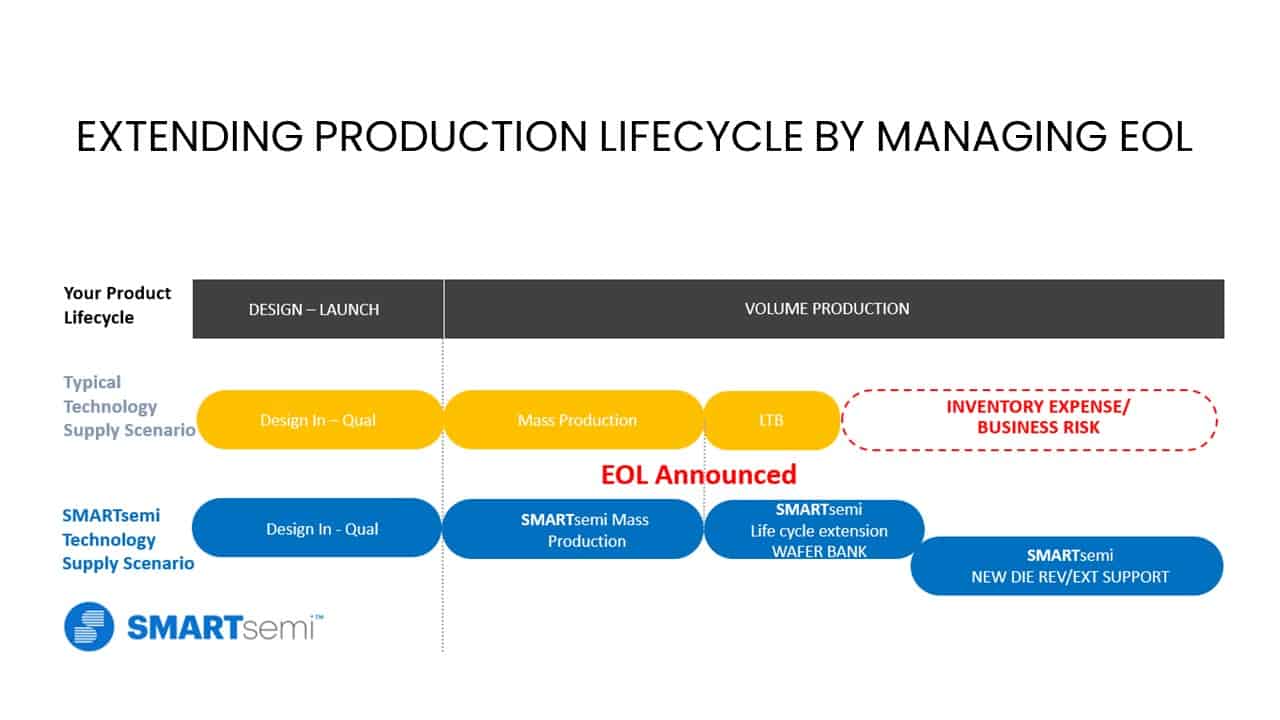

Manufacturers put out notifications for production end-of-life (EOL) and obsolescence to make room for the latest and greatest, while the semiconductor chip itself can last for many more years. Historically, semiconductor manufacturers announce EOL to save costs when the component’s target market is experiencing a downturn. For long-life applications, however, chip obsolescence is a guarantee. Durable products are usually built for over 30 years of service, while the integrated circuits they are equipped with will often be taken out of production in the course of five years.

Insight into the lifecycle of each of the used chip components allows engineers and designers of life-long applications to delay future redesigns and extend the overall product’s lifetime. Considering this information at the onset of a project lowers the risk of having to change course in the middle of the design stage and potentially missing delivery deadlines or creating recertification issues. During this exercise, cost trumps price as the cost of dealing with the aftermath of faulty, low quality, or counterfeit replacement components is far higher than the savings at purchase.

The role of the supplier

Today’s memory industry is an allocation market, making investing in supplier relationships a great tool to weather disruptions. A strong supply chain strategy incorporates a thorough sourcing and obsolescence plan, as well as reliable partners along the way, in good and bad times. It is straightforward for procurement to pay detailed attention to what is being bought. However, who you buy it from can often be the best approach to extend a product’s life, avoid last-time-buys (LTB), or inventory challenges. A good relationship between OEMs and component manufacturers/distributors is the foundation of effective obsolescence management. Transparency, trust, reliability, and capability are the hallmarks of a powerful partnership with an authorized distributor or manufacturer.

SMARTsemi is your supply chain partner for DRAM components, eMMC solutions, and SD/microSD Flash Memory Cards for long-life applications. With 20+ years of industry experience, we understand your challenges and have aligned our priorities with yours to simplify your memory chip supply chain for the long run. We know what you need before you need it. Get a jump start and request a sample today.